Overview of How to Design a Coin Yourself

Creating a coin design is an exciting adventure. Yet, as in any journey, one cannot do without a road map: in our case a detailed guide on how to design a coin. So, to answer the question “can I design my own coin online?” — we have prepared this article for you.

The following information will give you necessary details to navigate through the coin design-making process. We will break the arts of how to design a coin down to a series of peculiar phases a person needs to go through when making their own coin design flawless.

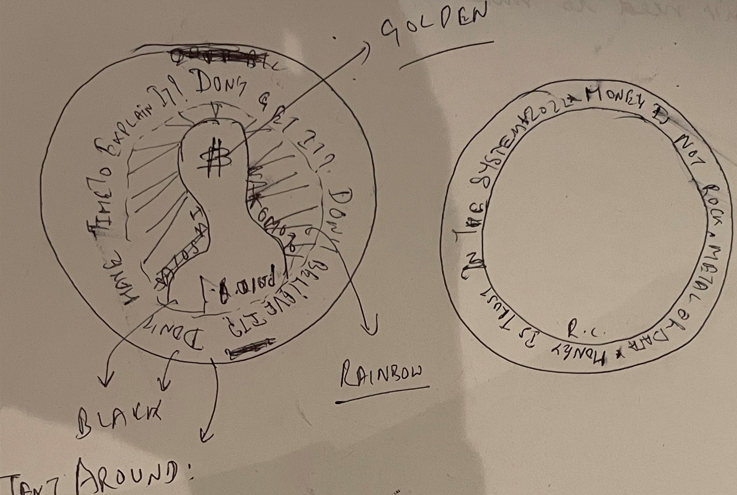

Phase 1 of How to Design a Coin: Brainstorming and Sketching

Every custom coin begins with an idea and how it will look. If you have a good imagination and know exactly what you want, you can sketch out a coin design right away. If the opposite is the case and you are at a loss, you can look at images in our Coin Gallery for inspiration. They will help you get a rough idea of what you would like your individual coins to look like. Keep in mind that both sides of the custom coins can have different appearances and you can put anything you want on them. This can be a photo, a picture, a logo, an emblem, texts, stripes, dots, lines or anything else you can think of and like. And contrary to current design trends, the more elements are on a coin, the more beautiful.

Once you have managed to put your thoughts together and decided approximately what you want to have embossed your custom-made coins with, it is time to enlist the help of a professional coin designer. Our design team at CoinsForAnything knows perfectly well how to design a coin. And even if your coin design consists of only a quick napkin sketch, they will make it look fabulous.

There is a great way to acknowledge and choose all custom coin design parameters right for you. Our website has a great tool, Online Coin Configurator. Here, you’ll be able to upload a picture you like if any, or use a prepared sample, experiment with various metals, coin borders, finishes, and add inscriptions on the commemorative coins’ surfaces.

Phase 2 of How to Design a Coin: Professional Refinement

When the brainstorming phase of how to design a coin is over, the coin designer proceeds to graphics creation for both sides of the custom coins and hands it to you for approval. If you are not completely happy with their first digital interpretation of your personal coin design, the specialist will take your comments and suggestions into account and add, take off, or review all elements you specify in the artwork.

The sketch and original elements are the most important parts when we start designing your own coin. Yet there are also other things to think about. Together with an expert, while creating the graphics for the front and back of the custom coins, you should discuss many other vital parts of coin design. These are the coins’ dimensions, metal for core and plating, relief, finish, colourisation and many more . You might already have encountered those when using our coin configurator. Our coin designers will assemble them all in your digital layout graphic. Let’s break them down one by one for your understanding.

Custom Coin Dimensions are Vital

When pondering how to design a coin, keep in mind the future medals’ size. It is directly linked to your artwork. For example, if your artwork involves an intricate pattern with multiple different elements, then the custom coins’ size should allow it to be fully revealed when embossed, i.e., be large enough. Standard dimensions for commemorative coins are 30mm to 55mm. However, at CoinsForAnything your custom-minted coins may be either smaller or larger in a range of 10mm up to 65mm or even more in diameter.

And, of course, among other things, the price of a finished piece is dependent on its size. Yes, the choice of metal for production of its core and plating, or the colour addition will affect the cost, but its size certainly doesn’t play the last part here. Smaller coins are often the best option when budgets are tight, but the product should be made of precious metal. Thus, there are many different aspects to consider when designing your own coin.

Consider Coin Thickness When You Think about How to Design a Coin

As we manufacture individualised coins, you are free to choose any thickness you feel is most appropriate. We are confident to emboss your custom coin design starting from 1.5 mm only. Bear in mind that the thickness of the custom coins also determines their weight. The thicker they are, the heavier.

If you wish for an inscription on your coins’ edges, we are happy to either emboss or laser engrave this on coins of minimum 4mm in thickness.

The ideal custom commemorative coin is one that is large enough to fully represent the artwork, yet small enough to fit every pocket, coin display or frame, and that feels good when you hold it in your hand.

The Base: What Metal do you want to make Custom Coins out of?

When putting your custom coin design together, think carefully about which metal to use to mint your individual coins. This choice will affect both their appearance in colour and weight, as well as their inherent value. Reflect on the very reason for minting these commemorative coins, the people they are being stamped for and, of course, weigh your finances well to know what you can count on.

When designing your own coin, you can choose ordinary metals like copper, brass, nickel, etc., or select precious metals like 24K pure gold or .999 fine silver.

What is the Best Way to Place Your Coin Design on or in the Metal?

There are several proven ways to apply the coin design to a coin blank. This are the ones we suggest:

- 2D/ 3D Embossing with 300 tons a attributes full customisation to your coin design. We adjust size, shape, finish, colour to pay tribute to your idea and work it at highest precision; additional enamel colours will make your commemorative coins burst into colour and fill them with inspiration;

- Die-casting for not only the optic effect, but for your coins to gain volume through a physical relief that literally makes them come to life;

- Engraving looks particularly chic on precious metal coins. We use a metal-preserving dotting technique that ensures you get all of what you purchased;

- Picture- or photo-printing turns the custom-made coins into a modern bright piece of art, covered with a dome of coin lacquer.

Phase 3 of How to Design a Coin: Use a Coin Configurator

There is a lot of information about how to design a coin mentioned above. At the same time, we assure you that these are not all the custom coin design options you can select and modify at your discretion. For example, you can also choose the metal plating, the type of enamel (hard or soft), the finish, and edges of the coin, etc.

There is a great way to acknowledge and choose the custom coin design parameters right for you. Our website has a great tool, an Online Coin Configurator Here, you’ll be able to download a picture you like if any, or use a prepared sample, experiment with various metals, coin borders, finishes, and add inscriptions on the commemorative coin surface.

Phase 4 of How to Design a Coin: Agreeing on Your Coin Moulds

When your sketch has been turned into a pleasant to the eye layout graphic, our coin designers hand on your project to our production team. Our colleagues will now envision how to transform this coin design idea into a solid metal piece. Before mill-cutting your personalised stamping tools, they will make a set of production graphics. These will illustrate how your coin design will be cut into the coin moulds. Due to the software we use, and certain details requiring to be adjusted manually, production graphics are not identical copies of the layout graphics they’re based on. Mind, that crafting coins is a manual art. Our craftsmen will ensure to stick the closest possible to your coin design. However, as customers, we need to compensate the desired metal’s rigidity with an ounce of flexibility when it comes to our imagination of the finalised coins.

Only once you have approved of this last step of how to design a coin, our team starts crafting the moulds and embossing your own design on a coin.

Order Custom Coins at Professionals

You have seen that it is possible to design a coin yourself, but it takes a lot of effort and time. Let’s get the coin design creation process started right away. You can fully rely on us as a professional coin manufacturer. The CoinsForAnything – coin design team is at your disposal. Contact us to find out more.

Disclaimer: Our products on this page are known as “Coins” in order to comply with general linguistic usage. It should be expressly pointed out that it concerns, however, individually embossed medals and no current or former means of payment/currency.